SOFC based machines have the advantage of being both fuel cells and electrolysers.

German version

See the German version

During times of extra renewable energy they can create hydrogen. During dunkelflaute they can then be reverse cycled to put energy back into the grid.

This is a huge advantage over other types of pure electrolyzers.

The system using these of course is more complex, so let’s take a look at the technology:

How They Work:

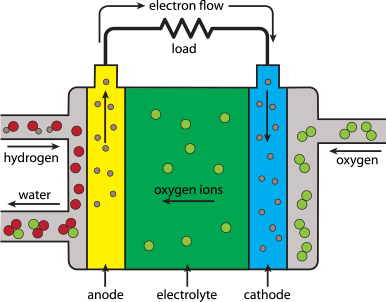

Electrolyte: Uses a solid ceramic material to conduct oxygen ions.

Temperature: Operates at high temperatures (700-1000°C).

Reaction: Electricity splits water molecules into hydrogen and oxygen ions.

The oxygen ions move through the solid ceramic to form oxygen gas.

Pros:

- Very high efficiency

- Can use both electricity and heat, making it ideal for integrating with industrial processes.

Cons:

- High operating temperatures require special materials and can be challenging to manage.

- Expensive and complex technology.

Due to these high pressure and temperatures NOT all heat exchangers can handle this.

If you are planning to build an electrolysis machine using this technology, you should look into THERMOGYM advanced stainless steel and other materials.

If you want to learn more about this technology I suggest the following:

NOTE: These are for reference and research ONLY, they should not been seen as recommendations or as any implications that there is any connections between Thermogym and these companies. These companies have very deep analysis of how the technology works, so if you want

From the hydrogen energy website

No related products or energy posts found.