One of the more popular methods of building electrolysis machines is to use the technology of PEM.

These machines can be from the hundreds of KW range to several Megawatts of power. In all cases there is the advantage that this is know technology and can easily be made. As in any system, scaling up from the stack to machines requires significant cooling. The power used in energy removal systems is lost power to the final user. Thus it is very important to find the correct way of cooling PEM electrolysers

How They Work:

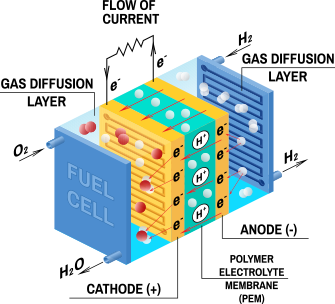

Electrolyte: Uses a solid polymer membrane (proton exchange membrane) to conduct protons from the anode to the cathode.

Electrodes: Catalysts at the anode and cathode help split water molecules.

Reaction: Electricity splits water into hydrogen ions (protons) and oxygen at the anode. The protons move through the membrane to the cathode, where they form hydrogen gas.

Pros:

- High efficiency and purity of hydrogen

- Quick response to changes in electricity input, making it good for renewable energy sources like solar or wind

Cons:

- More expensive due to the use of precious metal catalysts like platinum

- Shorter lifespan compared to alkaline electrolysers

If you want to keep your PEM based electrolyser cool, then you have to look at Thermogym. We have been experts in DI, De-ionized or De-minerilzed water for over 16 years.

Because this is a reaction that creates heat you have to find a way of cooling pem electrolysers.