Brazed Plate Heat Exchangers (BPHE) are compact, efficient devices used to transfer heat between two fluids.

They consist of a series of thin, corrugated metal plates that are brazed together to create a heat transfer surface.

Thermogym can design and provide all different types. Our strength is BOTH for standard liquids and DI water!

Thermogym can help you define the exact requirements for you. Let’s look at the important features.

Compared to other companies we can make these to extreme tolerances and requirements.

When you provide us with this data, we can design and produce these for your application.

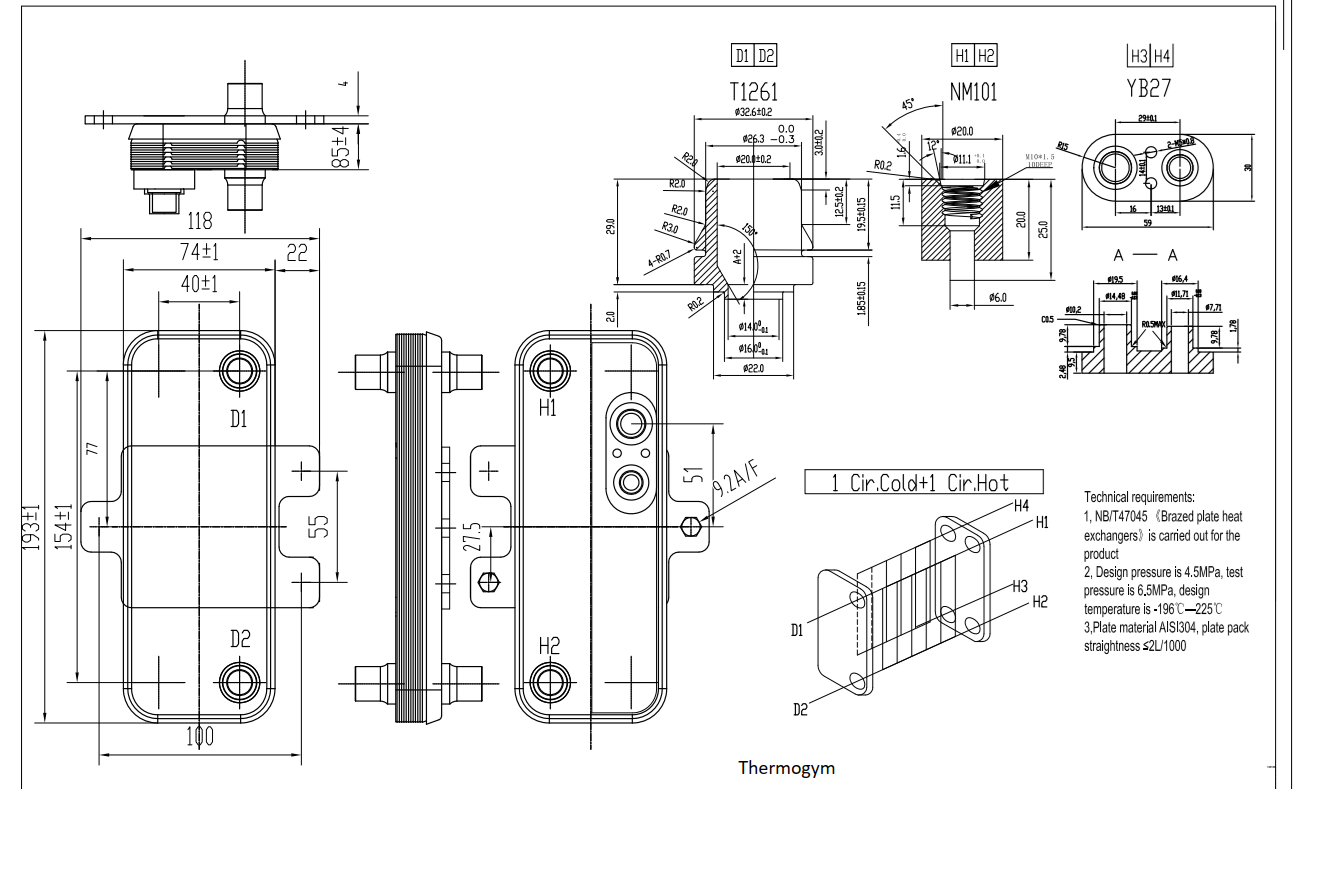

Structure and Design

- Plates: The primary components are the thin, corrugated plates, typically made of stainless steel. These plates are arranged in a stack and brazed together at the contact points using a copper or nickel-based filler material.

- Flow Channels: The corrugations on the plates create a series of channels through which the fluids flow. The plates are arranged so that the fluids flow in alternate channels, allowing heat to transfer through the plate walls.

- Compact Size: Due to the efficient design, BPHEs have a high heat transfer area relative to their size, making them much more compact than traditional shell-and-tube heat exchangers.

Working Principle

- Counter-Flow Arrangement: Typically, BPHEs operate in a counter-flow arrangement, where the fluids flow in opposite directions in adjacent channels. This maximizes the temperature difference between the fluids, enhancing heat transfer efficiency.

- Heat Transfer: As one fluid flows through the channels, it transfers heat to the plates. The heat is then conducted through the plates and transferred to the other fluid flowing in the opposite direction.

Applications

- HVAC Systems: Widely used in heating, ventilation, and air conditioning (HVAC) systems for heat recovery, space heating, and cooling applications.

- Refrigeration: Commonly used in refrigeration systems as evaporators, condensers, and economizers.

- Industrial Processes: Used in various industrial processes requiring efficient heat transfer, such as chemical processing, power generation, and food and beverage production.

- Renewable Energy: Employed in solar thermal systems, geothermal heating, and other renewable energy applications.

Advantages

- High Efficiency: The design allows for high heat transfer coefficients, resulting in efficient heat exchange.

- Compact and Lightweight: The compact design saves space and reduces the weight of the overall system.

- Cost-Effective: Often more cost-effective than other types of heat exchangers due to their efficient use of materials and high performance.

- Low Maintenance: With no moving parts and a sealed design, BPHEs typically require minimal maintenance.

Disadvantages

- Pressure Drop: The narrow channels can cause a significant pressure drop, which may require more powerful pumps.

- Fouling: While generally resistant to fouling, certain applications with dirty or viscous fluids can lead to blockages.

- Fixed Capacity: Unlike shell-and-tube heat exchangers, BPHEs have a fixed capacity and are not easily expandable.

Selection Criteria

- Temperature and Pressure: Ensure the BPHE can handle the specific temperature and pressure conditions of the application.

- Fluid Properties: Consider the thermal conductivity, viscosity, and potential fouling characteristics of the fluids.

- Flow Rates: Match the BPHE to the required flow rates for both fluids to ensure optimal performance.

- Material Compatibility: Select a BPHE with materials compatible with the fluids to prevent corrosion and ensure longevity.

Brazed Plate Heat Exchangers offer a highly efficient, compact, and cost-effective solution for many heat transfer applications, making them a popular choice across various industries.

THERMOGYM can support all different types of these. Including special inlets and outlets for all the different types.

Back to Technologies

No related products or energy posts found.